Order to Cash -

Working Capital Hub's

Self Assessment

Framework

Table of Content

- Sales Strategy & Contract Management

- Risk & Credit Management

- Order Management

- Invoice Issuance

- Terms

- Collections Management

- Dispute Management

- Liquidity Management

Introduction

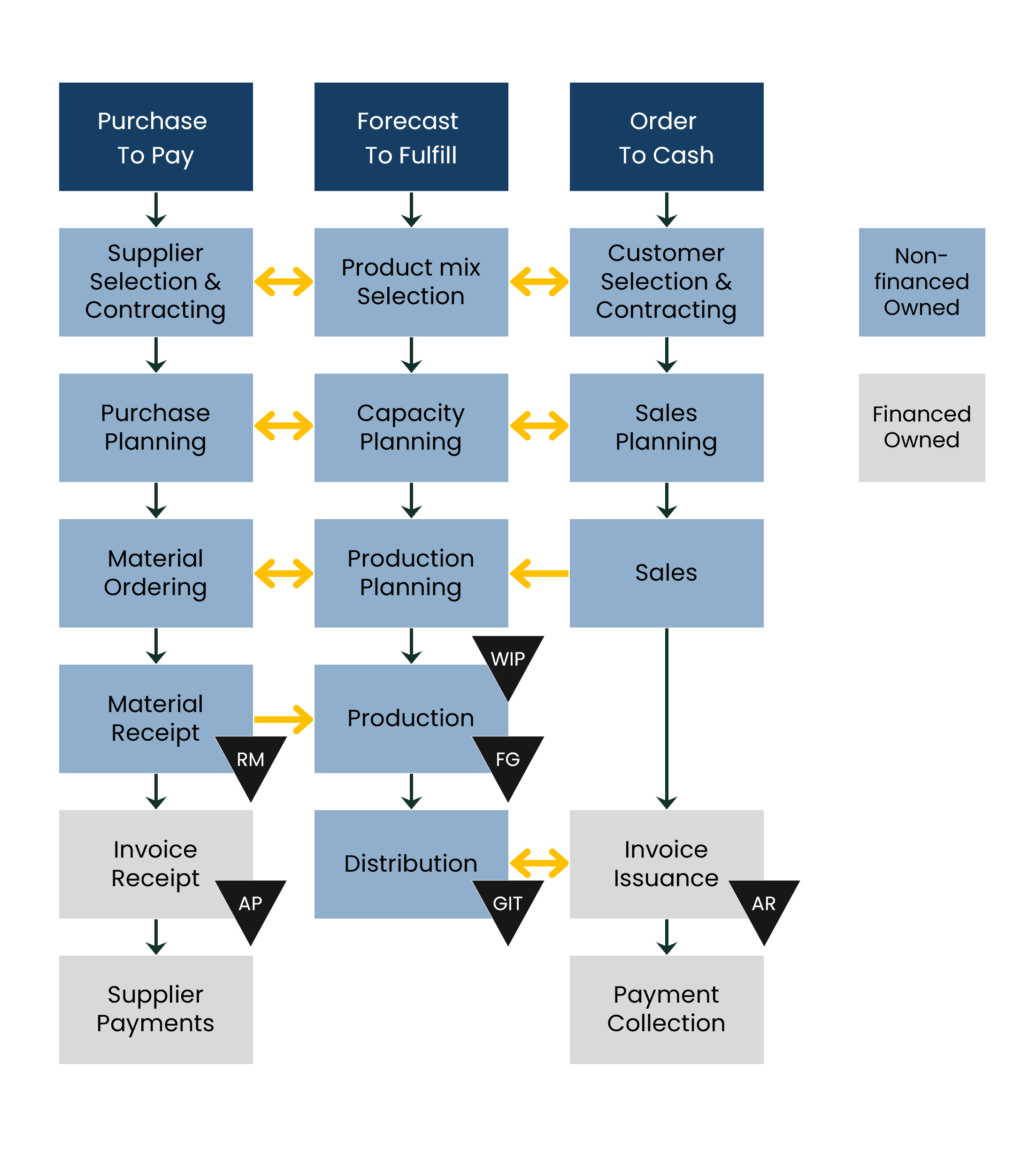

What is the Order to Cash Cycle?

Why the Order-to-Cash Cycle Matters

- Accelerates cash inflows → shortens Days Sales Outstanding (DSO) and improves liquidity.

- Strengthens customer relationships → ensures smooth ordering, accurate billing, and timely delivery.

- Reduces revenue leakage → prevents errors, disputes, and write-offs through accurate invoicing and credit control.

- Improves efficiency → lowers manual workload, reduces exceptions, and streamlines collections.

- Enhances resilience → provides visibility into receivables and customer payment behaviors, enabling proactive risk management.

- Supports profitability → by reducing bad debt, improving cash flow, and lowering financing costs

Order to Cash - Self Assessment Framework

Areas of Review in Working Capital Hub's OTC Self Assessment Framework

1. Sales Strategy & Contract Management

1.1. Sales Strategy & Credit Policy

- Strategy defined and in place, including standardized setup with dedicated resources.

- Central credit policy include guidelines for customer selection, segmentation and contract management, e.g., volume, credit assessment, terms, risk, limits and collection processes.

- A structured PLC policy and process in place guiding product development, growth, and discontinuation.

- Policy guidelines are aligned with overall business goals and market trends.

- Robust tools and dedicated cross-functional teams (e.g., R&D, sales, production) in place to ensure efficient workflows and seamless execution.

1.2. Contract Management Policy

- Customer contracts are standardized, including terms and conditions.

- Customer contracts are mandatory: usage is tracked and included in sales incentive structure.

- Customers cannot e created in master data without contracts.

- Accurate Bills of Materials (BoMs), including material requirements and standard costs, are maintained and continuously updated for each SKU (Stock Keeping Unit).

- BoM revisions are documented and effectively communicated to all relevant stakeholders across the organization.

- BoMs are seamlessly integrated with key systems such as ERP (Enterprise Resource Planning) and MRP (Material Requirements Planning) to ensure alignment and efficiency.

1.3. Sales metrics & Performance Targets

- Sales force KPI’s are defined, communicated and used as base for sales commission.

- KPI targets are continuously monitored and updated.

- Sales managers’ commission paid on or after date of cash receipt.

- Demand profiles and profitability by SKU are continuously analyzed and evaluated, providing critical input to the Product Life Cycle (PLC) process.

- Clear guidelines are established and actively enforced to determine when a product should be replaced or discontinued.

- Structured processes and guidelines are in place to ensure that discontinued or replaced products are effectively phased out and removed from the assortment.

2. Risk & Credit Management

2.1. Customer Risk Assessment

- Formalized and mandatory process and method for credit risk assessment in place.

- Risk and credit assessment made on both new and existing customers.

- External credit rating agency used to evaluate customers.

- Formalized process in place to ensure sales forecasts and demand plans are regularly generated using the best available historical data and market insights.

- Sales forecasts and demand plans are separate from the overall sales plan and provide an unbiased view of gross demand (i.e., without accounting for current inventory levels).

- The time horizons, frequency, and level of granularity of the forecasts are aligned with operational demand planning requirements and serve as key inputs to recurring S&OP (Sales and Operations Planning) meetings.

2.2. Credit Approval &

Limits

- Credit risk policy and workflow in place, including roles and responsibilities for approval of credit limits.

- Credit limits are calculated based on credit rating, expected sales and agreed payment terms.

- Advanced tools and technologies (e.g., predictive analytics or AI) is used to enhance forecasting capabilities.

- The forecasting and demand planning tool can handle various level of granularity (e.g., SKU, region, time horizon) and accommodate scenario planning.

- Forecasting and demand planning tools are integrated with key systems like ERP or supply chain management tools.

2.3 Credit Limit Management & Risk

- Customers’ credit and financial stress scores are regularly reviewed to realign credit limits and collection approach.

- Feedback loop to Sales and Collections of updated credit status is in place.

- System automatically places delinquent customers on ‘credit hold’.

- Forecasts and demand plan accuracy are tracked and reviewed regularly, with updates made to reflect real-time changes in customer behavior or market conditions.

- Feedback loops are in place to identify forecasting errors and implement corrective actions.

3. Order Management

3.1. Order Entry (Process & Accuracy)

- Standardized core order-entry and order-management process in place.

- Orders are received through EDI or web based order-entry and management system.

- A formalized process (e.g., Integrated Business Planning) is in place to evaluate future capacity requirements based on the overall business plan, updated forecasts, and current supply chain conditions and constraints.

- Current resource capacity constraints, including labor, equipment, and facilities, are thoroughly mapped and understood.

- Strategies and contingency plans, such as capacity buffers, adding shifts, outsourcing, or capital investments, are defined and readily available for both short- and long-term capacity adjustments.

3.2. Contract Administration

- All contracts stored and managed electronically by dedicated resources.

- Standardized customer contract management practices are in place.

- System informs relevant stakeholders of forthcoming contract expirations

- A formalized process is in place to ensure supply plans are generated using the latest demand plans, available capacity, inventory levels, and service level requirements, and serve as key input to recurring S&OP (Sales and Operations Planning) meetings.

- Supply plans are aligned with procurement to confirm material availability, considering replenishment lead times and potential supply chain risks.

3.3 Order Fulfillment

- Single system to integrate customer service, logistics data and transactions in place.

- Order processing include: availability of goods, timing of delivery and communication between logistics and order entities.

- Order related issues are actively reported and analyzed to determine root causes.

- Available systems provide visibility of inventory levels, capacity and production schedules across multiple locations.

- Advanced tools and technologies (e.g., workflow and capacity planning) is used to enhance supply planning capabilities.

- Demand plans are automatically converted to material requirements, based on latest available bill of materials (BoM).

4. Invoice Issuance

4.1. Invoicing Frequency, Triggers & Approval

- Standard policy and process in place re: timing of invoice issuance and dispatch approval.

- Automatic interface between logistics and billing systems in place to ensure accurate and timely invoices are produced and dispatched to the right customer entity daily.

- Invoicing delay monitored and tracked.

- A formalized S&OP process is in place, with meetings held at regular intervals and cross-functional participation from Sales, Production, Purchasing, Logistics, and Finance.

- The S&OP process reviews customer demand and supply resources, delivering a consensus plan across an agreed rolling horizon.

- The S&OP meetings also routinely evaluate the execution of the consensus plan and adjust plans as needed based on outcomes.

4.2. Invoice Content, Format & Quality

- Standard invoice design in place.

- All relevant information is displayed on the invoice, including due date.

- Frequent random checks carried out to check invoice terms vs. contract terms.

- Invoice quality monitored and tracked.

- All agreed-upon plans align with overall business strategy, and conflicts or disagreements are resolved collaboratively with focus on achieving the best outcome of the business.

- All S&OP meeting decisions are documented, with clear ownership and timelines assigned for action items.

- All agreed-upon action items are tracked and followed up in subsequent meetings.

4.3 Invoicing Methods

- Customers are invoiced electronically or via EDI.

- No paper invoices sent unless specifically required and agreed with customer.

- Relevant S&OP metrics, such as forecast accuracy, service levels, inventory, capacity utilization and plan attainment, are reviewed and discussed during S&OP meetings.

- Deviations from plans or targets are identified and addressed as part of the S&OP process, with corrective actions agreed upon, implemented, and followed up.

5. Terms

5.1. Standard Payment Terms

- Standard payment terms and conditions defined, including guidelines for application and restrictions for use, and communicated across the organization.

- Customer terms and conditions are also aligned with risk profiles and customer segmentation setup.

- Use of payment terms monitored and controlled.

- Formalized process in place for production planning and scheduling, including frozen time horizons (where no changes are allowed).

- Production plans and scheduling are aligned with agreed consensus plan, with little or no changes to volume or product type.

- Critical parameters such as base quantities, set-up times, lead times and bottle necks are understood and actively used in production planning and scheduling.

5.2. Negotiation Rules & Thresholds

- Customer negotiation policies in place, including defined processes to manage and reduce negotiation time.

- Deviation from standard terms and conditions must always be signed off by senior management.

- Sales staff are trained to understand how terms and conditions are to be applied and effect the business (e.g., profitability, working capital etc.)

- Unplanned downtime of production assets are minimized through proactive maintenance and effective scheduling.

- Robust quality control measures in place to address issues early in the process. Production output generally meets quality standards with minimal rework or defects.

- Continuous improvement initiatives are common to enhance production reliability, throughput and quality.

5.3. Net vs. End-of-Month Terms & Early Payment Discounts

- End of month terms and early payment discounts are generally not standard and requires senior level approval.

- Production planning software is in place, integrating inventory, sales, and production data.

- Relevant metrics, such as Overall Equipment Effectiveness (OEE), capacity utilization, plan attainment, and plan stability, are visibly displayed on performance boards, and reviewed and discussed during daily and weekly planning and production meetings.

- All productivity targets are defined and set to avoid incentivizing production volumes above planned levels.

6. Collections Management

6.1. Collection Process

- Differentiated collection process and approach in place, sensitive to customer characteristics (size, credit risk, historical payment performance, etc.).

- Dunning letters automatically sent supplemented by follow up phone calls.

- Proactive calling is used for habitual late payers to ensure timely payment

- Differentiated stock holding and replenishment strategy and service level requirements set by SKU category, where parameters are defined based on e.g., demand profile, volume and value (e.g., ABC, XYZ).

- Formalized process in place to ensure inventory replenishment parameters such as lead time, batch sizes, production rates and minimum order quantities (MOQ) are continuously updated to reflect reality.

- Formalized process in place to ensure planning assumptions such as re-order points, re-order frequencies, and safety stock requirements are continuously reviewed and updated.

6.2. Customer Segmentation

- Customers are segmented based on credit risk assessment, share of value, outstanding amounts, and payment history.

- Prioritization criteria is used to target top revenue-producing and top aged-A/R-producing customers (habitual late payers).

- Integrated real-time inventory management system is used to monitor and identify slow moving and obsolete stock (SLOB).

- Documented and applied clearance processes are in place.

- Sales incentive structures include performance on SLOB clearance.

6.3. Bad Payer Management

- Process in place for handling habitual late payers, and included in day-to-day collection process.

- Pro-active dunning calls performed for sporadic bad payers.

- Escalation protocol for habitual offenders is in place and actively used.

- Integrated real-time inventory management system with automated replenishment alerts is used to manage inventory mix and levels.

- Relevant inventory management metrics, such as days inventory outstanding (DIO), service level, SLOB%, stock out rates and cassation are reviewed and discussed during planning meetings.

- Inventory targets set and continuously monitored and updated.

- Inventory records are accurate, regularly updated, and reconciled with physical stock.

7. Dispute Management

7.1. Dispute Identification & Resolution

- Formalized dispute resolution process implemented and enforced – including early dispute identification, dispute coding, escalation process, etc.

- Resolution of disputes supported by sales organization to effectively manage customer relationship.

- Dispute resolution time monitored and controlled.

- Warehouses are positioned at strategic locations to balance proximity to demand centers and cost efficiency.

- Warehouse layout and processes are optimized for efficient picking, packing and storage.

- Inventory storage systems, such as shelving and pallets, are designed to maximize space utilization, optimize first-in-first-out (FIFO) and reduce handling time.

7.2. Root Cause Identification

- Disputes tracked on regular basis and presented split by dispute code.

- Formalized process in place to routinely perform root cause analysis and targeted improvement initiatives on identified dispute codes.

- Transportation routes and schedules are optimized to minimize lead times and delivery costs.

- Contingency plans are in place to manage delays, disruptions, or unexpected demand spikes.

- Any third-party logistics (3PL) providers, if used, are continuously evaluated for cost-effectiveness and service quality.

7.3. Credit Note Process & Management

- Responsibility and approval rights are effectuated and communicated to organization.

- All credit note contains link to original invoice ID for efficient tracking and follow-up.

- Partially disputed invoices are credited in full where agreed amount is invoiced immediately with no credit time (if original invoice is past due date).

- Credit note quantity and amounts are tracked and evaluated periodically.

- Warehouse and logistics planning systems are integrated with inventory management systems to synchronize stock updates.

- Transportation, warehousing, and handling costs are regularly tracked and analyzed for potential improvements.

8. Liquidity Management

8.1. Payment Methods

- Corporate payment policy in place and communicated to all customers.

- Payment policy restricts payment methods to electronic transfer types.

- Warehouses are positioned at strategic locations to balance proximity to demand centers and cost efficiency.

- Warehouse layout and processes are optimized for efficient picking, packing and storage.

- Inventory storage systems, such as shelving and pallets, are designed to maximize space utilization, optimize first-in-first-out (FIFO) and reduce handling time.

8.2. Ledger & Account Reconciliation

- Process of reconciling ledger with account, including the use of tools and methods to track performance and capture inconsistencies, in place.

- Consistent reconciliation process enabled by standard templates.

- Centralized monitoring of differences and completeness.

- Dashboards and reports provide completeness validations and error tracking.

- Transportation routes and schedules are optimized to minimize lead times and delivery costs.

- Contingency plans are in place to manage delays, disruptions, or unexpected demand spikes.

- Any third-party logistics (3PL) providers, if used, are continuously evaluated for cost-effectiveness and service quality.

8.3. Cash Application & Unallocated Cash

- Formalized cash application process including in place.

- Applied payments are classified into appropriate classes (pre-payments, duplicate payments, unallocated etc.) allowing for accurate cash collection forecasting and performance metrics.

- Root causes of non-automatic matching reviewed and discussed with customer.

- Warehouse and logistics planning systems are integrated with inventory management systems to synchronize stock updates.

- Transportation, warehousing, and handling costs are regularly tracked and analyzed for potential improvements.